The CLS Fabrication Story

Sheet metal fabrication centers on converting flat sheets of metal to create structures, components, and products. This manufacturing process involves various techniques — such as laser-cutting, punching, bending, welding and machining — to transform sheets of aluminum, steel, or stainless steel into the desired form. It is crucial in multiple industries, particularly construction, manufacturing, automotive, aerospace, and infrastructure development.

CLS Fabrication has become a trusted name for sheet metal fabrication. Since 1985, we have thrived as a major producer of OEM sheet metal products through collaborative client partnerships. We remain at the forefront of technology, leveraging our expertise to discover innovative solutions that guarantee the success of our projects. Today, we continue to provide top-notch materials and first-rate services with a commitment to continuous improvement and investment in cutting-edge technology.

From Humble Beginnings

Eric and Barbara Fleming founded CLS Fabrication in their home’s garage in Costa Mesa, California. The company started as a small operation, initially crafting coin-operated laundry machine security devices – hence the name, Coin Laundry Security (CLS) Fabrication. Later, the growing company expanded its offerings to include commercial and general security products, third-party sheet metal solutions, and eventually its own line of high-end, metal garage cabinets with a name that’s hard to forget – Baldhead Cabinets.

Recognizing the need for expansion, the company relocated its operations to central Oregon in 2005. Now, we boast a state-of-the-art facility fully equipped with cutting-edge technologies and machinery to ensure operational efficiency and success.

Our Advanced Machinery and Equipment

CLS Fabrication’s investment in the latest tools and technology is a cornerstone of its success, driving efficiency across various manufacturing processes to deliver high-quality products. Here are some of our prized pieces of equipment:

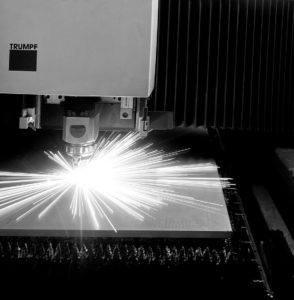

Trumpf Laser Cutting/Punching/Bending

We have strategically invested in a comprehensive array of Trumpf CNC equipment. These advanced machines are pivotal in shaping the company’s manufacturing capabilities, ensuring high-quality outputs and a streamlined production workflow. Brand loyalty really matters when it comes to precision sheet metal processing, and Trumpf has proven a worthy partner. Having continuity within and across machine categories and technologies affords us a very robust maintenance regime, which includes machine performance data collection and monitoring both on and off-site, which in turn helps us ensure our equipment is consistently running in optimal condition.

Fiber Lasers

For precise fiber laser cutting, we have the Trumpf TruLaser 3040 in 4000- and 8000-watt configurations. It has advanced features like lights-out automation and auto-loading/unloading capabilities. Its large 4-meter format cutting area (80” x 160” sheet size maximum) efficiently handles materials up to 1” thickness, including SS, AL, and Carbon Steel. Meanwhile, the laser configuration incorporates advanced capabilities such as automatic nozzle changing, flying optics, and fiber optic beam delivery.

CNC Punch

CLS Fabrication relies on the Trumpf TruPunch 5000 for various tasks, including punching, tapping/extruding, embossing/debossing, and perforation. It can handle sheet sizes up to 60” x 120” and materials up to 5/16” thickness in SS, AL, Carbon Steel, and red metals. With a full rotation on all tool stations, this punch press allows tapping and scoring of material. The machine also has automatic sheet loading, part sorting, and unloading features, ensuring precision and convenience.

CNC Press Brakes

The Trumpf TruBend series, comprising models such as the TruBend 5230, 5170, 5130, and 7036, demonstrates CLS Fabrication’s commitment to excellence in bending and forming. These machines have varying press forces, bending lengths, and features like tight tolerances, a vast tooling catalog, and offline programming to produce consistently formed parts.

Vertical Machining Center

The Doosan DNM6700 Vertical Machining Center adds a new dimension to our services. Featuring 3-axis vertical machining, CNC control capabilities, and a table size of 59” x 26”, it accommodates a wide range of machining tasks. The machine’s capabilities cover a comprehensive array of operations — including milling, drilling, threading, and profiling — working with materials ranging from alloy steel to polycarbonate.

Welding, Fabricating, and Fixturing With Human Craftsmanship and Siegmund Tables

The company has undergone a transformative shift in welding technology — moving from traditional methods for fixturing to cutting-edge equipment, enhancing the work environment and output quality. Primarily, the introduction of four new welding tables has revolutionized our day-to-day operations for our skilled and seasoned welders.

Our Advanced TIG, MIG, Spry-Arc, and Resistance welding machines are designed to provide superior performance, precision, and control. Meanwhile, the Siegmund tables — known for their super high precision — have replaced our old flat steel plate setup. This provided a machined surface for pin fixturing that accelerates the welding process and ensures higher accuracy and throughput.

Powder-Coating System

CLS Fabrication boasts a 3-stage iron-phosphate, pretreatment wash system, which provides an extra layer of corrosion-resistance to the parts they powder-coat, and enables a smooth and consistent finish. The entire system is driven by an overhead conveyor line for high-volume, maximized throughput, from hanging, washing, applicating, curing, inspecting, and unloading. The fluidized hoppers, and advanced manual spray guns provide the experienced applicators flexibility for even the most intricate and difficult part geometry.

Additional Fabrication Machines

CLS Fabrication continues to spearhead technological advancements by incorporating new machines dedicated to part leveling, band & cold saw material cutting, surface finishing, and edge deburring. These additions are designed to elevate the quality of manufactured parts, setting a new standard for what customers can anticipate from us.

The company also recently visited the Trumpf Smart Factory in Chicago as part of its strategic plans. The guided tour provided the CLS Fabrication team with valuable insights into the latest equipment, innovations, and advanced automation technologies. This helps us stay at the forefront of industry trends, ensuring that our operations align with the most advanced and efficient practices.

The CLS Philosophy

Our philosophy at CLS Fabrication revolves around a simple yet powerful principle: putting people first. This core belief is reflected in the company’s approach to its employees and customers, shaping how we conduct business and fostering a supportive work environment.

Elevating Employee Experience and Skills

CLS Fabrication has earned a reputation as a company where the employees are valued, some having dedicated over 32 years to the company. Our employees are our greatest asset. We provide them with the tools needed to create more complex parts and products more efficiently, making their jobs more interesting. The more mundane tasks are handled faster by specific machinery, leaving more time for their skills to be showcased with our equipment’s more technically advanced capabilities.

At CLS Fabrication, we believe our employees are enabled by better technology and are prouder, happier, and more engaged in their work. This leads to a higher level of customer satisfaction and the overall production of higher precision products. Implementing cutting-edge technology ensures that CLS Fabrication, our clients, and our employees directly benefit from technological advancements, making their tasks more manageable and rewarding

The company also places a significant emphasis on employee education and training programs. Our primary goal is to empower employees with the skills and knowledge required to excel in their roles. This fosters a sense of confidence and competence among the workforce. Beyond professional skills, these training programs contribute to employees’ personal growth, nurturing a culture of lifelong learning.

Fostering Client-Centric Excellence

CLS Fabrication positions itself as a trusted and exceptional service provider dedicated to delivering custom-made solutions and maintaining excellence in the fabrication industry. We stand out in the competitive landscape by emphasizing collaboration and adaptability to optimize quality and manufacturing efficiency.

The company views client interactions as opportunities for ongoing, long-term collaboration. We aim to build trust and deliver excellence through investment in the latest technologies and continuous adaptation to evolving client needs. This commitment positions us as a strategic partner capable of tackling the most challenging projects in the industry.

Choose CLS Fabrication for Innovative Steel Fabrication Solutions!

If you need premium steel products and components crafted with precision and modern finishes, partner with CLS Fabrication! We are a leading manufacturer and supplier for all your sheet metal fabrication needs — from fiber laser cutting and CNC punching to welding and powder coating.

Our seasoned team brings years of expertise and a steadfast commitment to tried-and-tested craftsmanship, ensuring top-notch quality in every project we handle. We consistently reinvest in new technologies and equipment to deliver reliable results and provide high-precision goods tailored to your unique needs.

Contact us today to discuss your requirements and experience the difference of working with industry-leading fabrication experts!