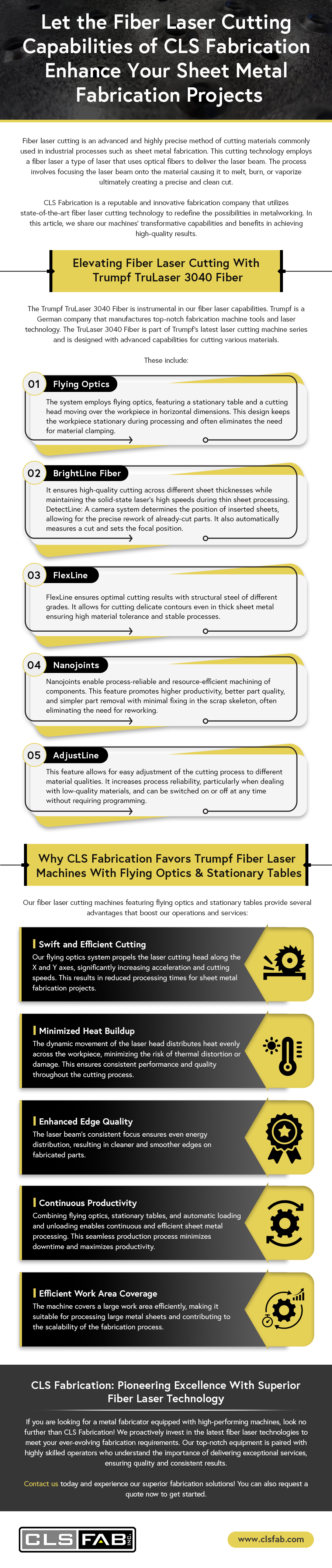

Let the Fiber Laser Cutting Capabilities of CLS Fabrication Enhance Your Sheet Metal Fabrication Projects

Fiber laser cutting is an advanced and highly precise method of cutting materials commonly used in industrial processes such as sheet metal fabrication. This cutting technology employs a fiber laser a type of laser that uses optical fibers to deliver the laser beam. The process involves focusing the laser beam onto the material causing it to melt, burn, or vaporize ultimately creating a precise and clean cut.

CLS Fabrication is a reputable and innovative fabrication company that utilizes state-of-the-art fiber laser cutting technology to redefine the possibilities in metalworking. In this article, we share our machines’ transformative capabilities and benefits in achieving high-quality results.

Elevating Fiber Laser Cutting With Trumpf TruLaser 3040 Fiber

The Trumpf TruLaser 3040 Fiber is instrumental in our fiber laser capabilities. Trumpf is a German company that manufactures top-notch fabrication machine tools and laser technology. The TruLaser 3040 Fiber is part of Trumpf’s latest laser cutting machine series and is designed with advanced capabilities for cutting various materials. These include:

- Flying optics: The system employs flying optics, featuring a stationary table and a cutting head moving over the workpiece in horizontal dimensions. This design keeps the workpiece stationary during processing and often eliminates the need for material clamping.

- BrightLine Fiber: It ensures high-quality cutting across different sheet thicknesses while maintaining the solid-state laser’s high speeds during thin sheet processing.

- DetectLine: A camera system determines the position of inserted sheets, allowing for the precise rework of already-cut parts. It also automatically measures a cut and sets the focal position.

- FlexLine: FlexLine ensures optimal cutting results with structural steel of different grades. It allows for cutting delicate contours even in thick sheet metal ensuring high material tolerance and stable processes.

- Nanojoints: Nanojoints enable process-reliable and resource-efficient machining of components. This feature promotes higher productivity, better part quality, and simpler part removal with minimal fixing in the scrap skeleton, often eliminating the need for reworking.

- AdjustLine: This feature allows for easy adjustment of the cutting process to different material qualities. It increases process reliability, particularly when dealing with low-quality materials, and can be switched on or off at any time without requiring programming.

Why CLS Fabrication Favors Trumpf Fiber Laser Machines With Flying Optics & Stationary Tables

Our fiber laser cutting machines featuring flying optics and stationary tables provide several advantages that boost our operations and services:

Swift and Efficient Cutting

Our flying optics system propels the laser cutting head along the X and Y axes, significantly increasing acceleration and cutting speeds. This results in reduced processing times for sheet metal fabrication projects.

Minimized Heat Buildup

The dynamic movement of the laser head distributes heat evenly across the workpiece, minimizing the risk of thermal distortion or damage. This ensures consistent performance and quality throughout the cutting process.

Enhanced Edge Quality

The laser beam’s consistent focus ensures even energy distribution, resulting in cleaner and smoother edges on fabricated parts.

Continuous Productivity

Combining flying optics, stationary tables, and automatic loading and unloading enables continuous and efficient sheet metal processing. This seamless production process minimizes downtime and maximizes productivity.

Efficient Work Area Coverage

The machine covers a large work area efficiently, making it suitable for processing large metal sheets and contributing to the scalability of the fabrication process.

CLS Fabrication: Pioneering Excellence With Superior Fiber Laser Technology

If you are looking for a metal fabricator equipped with high-performing machines, look no further than CLS Fabrication! We proactively invest in the latest fiber laser technologies to meet your ever-evolving fabrication requirements. Our top-notch equipment is paired with highly skilled operators who understand the importance of delivering exceptional services, ensuring quality and consistent results.

Contact us today and experience our superior fabrication solutions! You can also request a quote now to get started.